- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the rapidly evolving landscape of manufacturing technology, Bellows CNC products stand out for their unique features and diverse applications. These specialized solutions have been designed to enhance precision and efficiency in various industrial settings, from automotive to aerospace. This blog will delve into the innovative aspects of Bellows CNC, highlighting their capability to protect critical machinery components from contaminants while also providing flexibility and motion support. By exploring the unique characteristics of these products, we aim to illuminate their essential role in modern manufacturing processes. Whether you are a seasoned professional or a newcomer to the field, understanding the benefits and applications of Bellows CNC products can significantly impact operational effectiveness and productivity. Join us as we uncover the fascinating world of these top-tier solutions and their contributions to advanced manufacturing techniques.

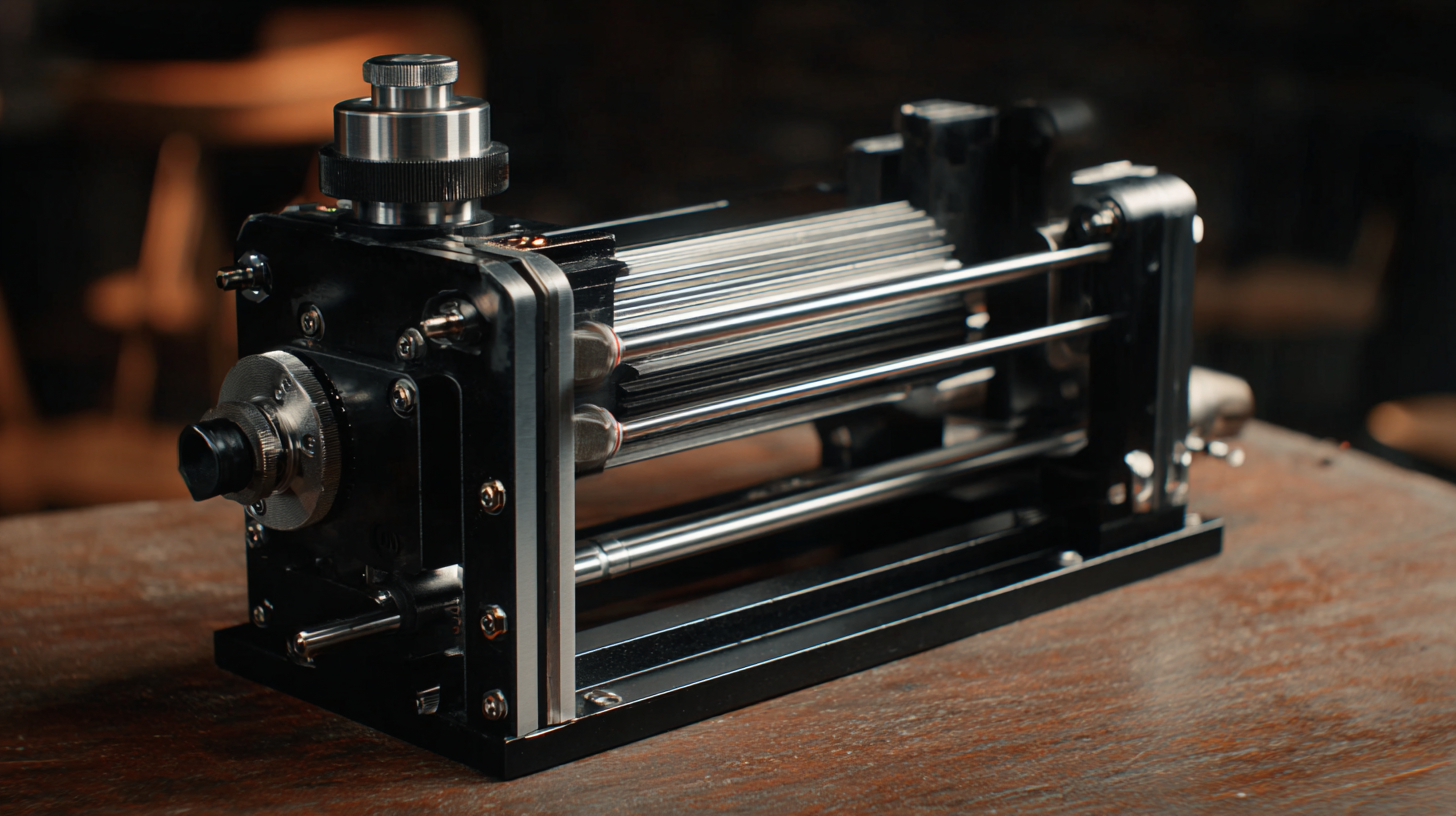

When it comes to precision engineering, high-quality bellows CNC products stand out due to their unique characteristics. These components are commonly used in various industries, including aerospace, automotive, and robotics, owing to their ability to provide excellent sealing and protection against environmental factors. One essential characteristic of top-tier bellows products is their adaptability in extreme conditions; they can withstand high temperatures and pressures while maintaining functionality. Additionally, the materials used in their construction, such as elastomers or metals, contribute significantly to their durability and resilience.

Another crucial aspect of high-quality bellows CNC products is their customizable design. Manufacturers can tailor bellows to specific applications, ensuring optimal performance and longevity. This customization includes variations in size, shape, and material properties, allowing engineers to meet the precise requirements of their projects. Moreover, advanced CNC machining techniques facilitate the production of intricately detailed bellows, which enhances their efficiency and reliability in critical applications. This level of versatility makes them indispensable in modern manufacturing, as they not only improve product lifespan but also reduce maintenance costs.

This bar chart illustrates the top five essential characteristics of high-quality bellows CNC products, showcasing their performance in various key areas such as durability, flexibility, heat resistance, precision, and cost-effectiveness. Each characteristic is rated on a scale of 1 to 10, providing a visual representation of their importance in the industry.

The applications of bellows CNC technology are expanding rapidly across various industries, fueled by the growing demand for precision and flexibility in manufacturing. As the global CNC machine market is projected to grow from $101.22 billion in 2025 to approximately $195.59 billion by 2032, at a compound annual growth rate (CAGR) of 9.9%, advancements in bellows technology are playing an integral role in this transformation. Industries such as automotive, aerospace, and electronics benefit significantly from the versatility and reliability of bellows CNC products, which help in safeguarding delicate components from environmental contaminants and mechanical wear.

Furthermore, the market for machine tools is also on the rise, with an estimated growth from $13.63 billion in 2025 to $22.94 billion by 2032, reflecting a CAGR of 8.1%. This growth trajectory highlights the critical importance of incorporating innovative technologies like CNC machining to meet the increasing production demands. In addition, recent developments such as mobile applications allowing remote monitoring of CNC machines offer operators greater control and efficiency, further enhancing the operational capabilities of industries that rely on precision engineering. As these technologies evolve, the significance of bellows CNC products in maintaining productivity and ensuring quality will undoubtedly continue to grow.

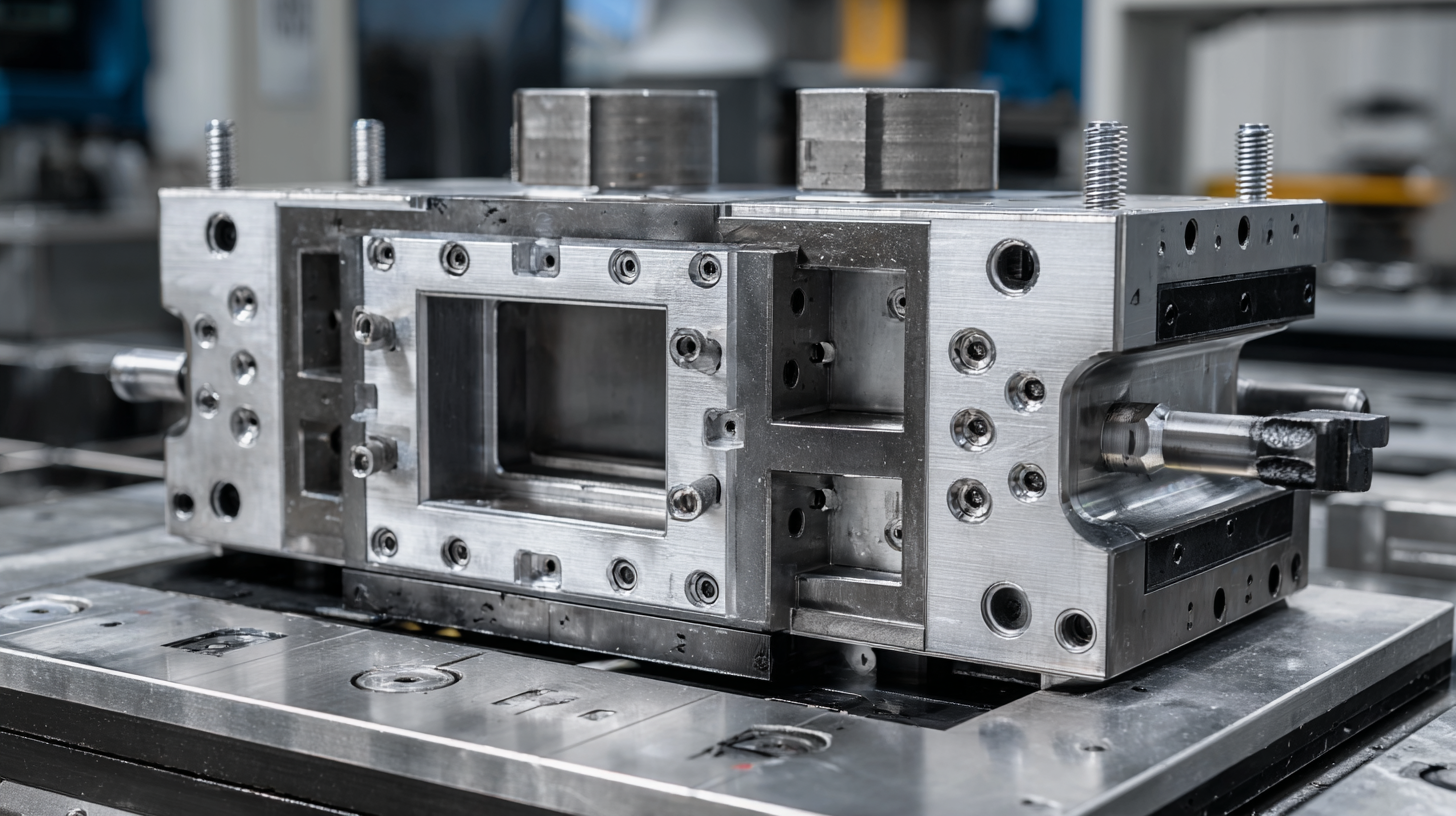

When choosing a reliable bellows manufacturer, several critical factors must be considered to ensure quality and performance. First and foremost is the manufacturer's experience and reputation in the industry. A company with a long-standing history and a solid reputation for producing high-quality bellows can be a reliable indicator of their expertise and commitment to customer satisfaction. Checking their portfolio and customer reviews can provide valuable insights into their capabilities and service.

Another essential factor is the materials used in the production of bellows. Different applications may require specific materials that can withstand various environmental conditions, such as temperature fluctuations, chemical exposure, or pressure variations. Therefore, it's crucial to discuss material options with potential manufacturers to ensure they can meet the unique requirements of your application. Finally, consider the manufacturer's adherence to industry standards and certifications, as this reflects their dedication to quality control and product reliability. By carefully evaluating these factors, you can make an informed decision when selecting a bellows manufacturer tailored to your needs.

| Feature | Description | Application Area | Material Options |

|---|---|---|---|

| Temperature Resistance | Ability to withstand high and low temperatures without deforming. | Aerospace, Automotive | Silicone, PTFE |

| Chemical Resistance | Resilience against harsh chemicals and solvents. | Pharmaceutical, Chemical Processing | EPDM, Viton |

| Flexibility | Ability to bend and expand without damage. | Medical Equipment, Robotics | Rubber, Neoprene |

| Durability | Long-lasting performance in demanding environments. | Construction, Machinery | Polyurethane, Steel |

| Customizability | Options for bespoke designs to fit specific applications. | Various Industries | Multi-layer Composites |

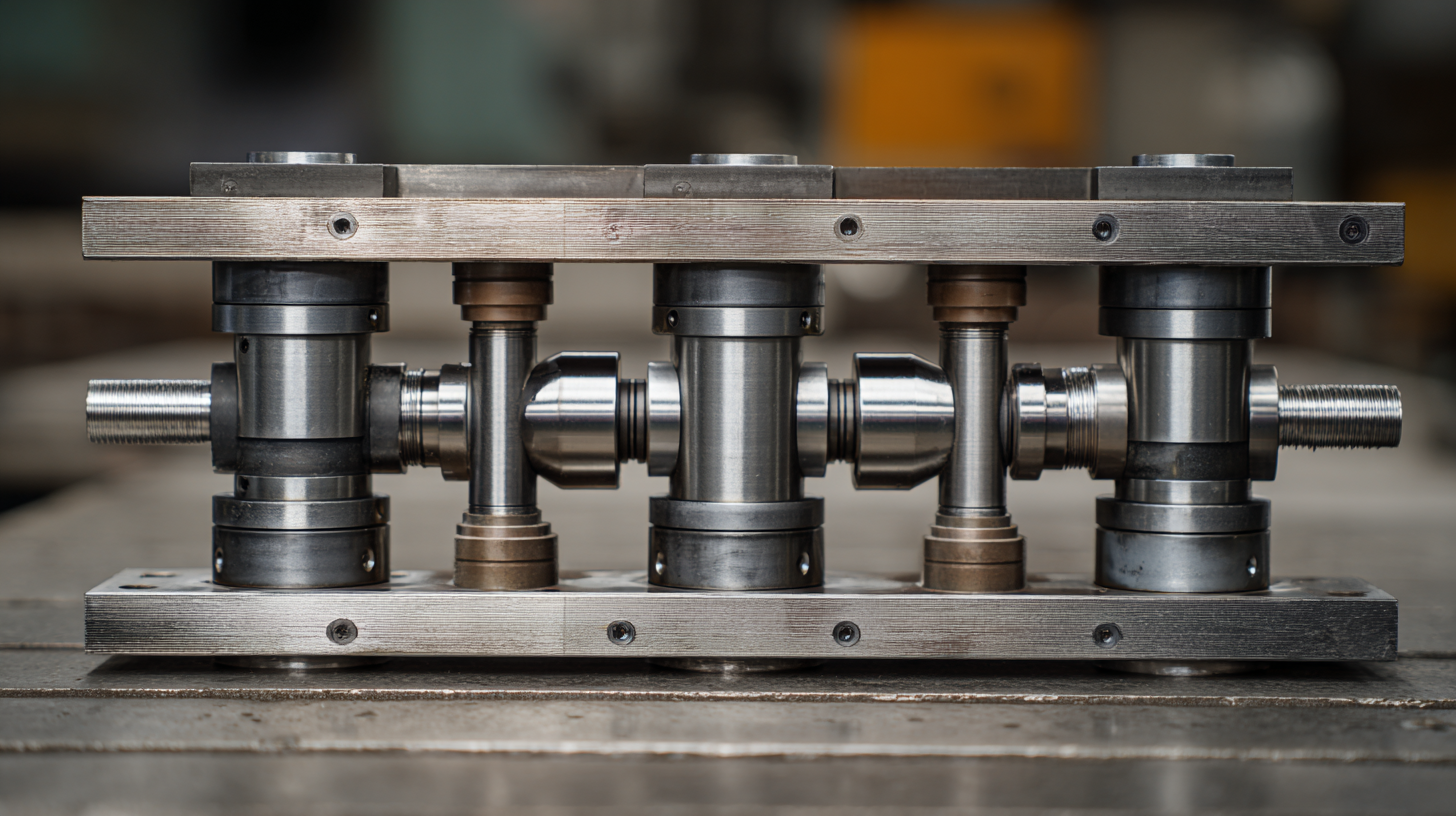

When evaluating the quality of Bellows CNC products, several key factors must be considered to ensure that they meet both performance and durability standards. First and foremost, material quality is crucial; products made from high-grade materials such as polyurethane or silicone offer enhanced flexibility and resistance to wear. According to a recent industry report by TechSci Research, the global market for CNC bellows is projected to grow significantly, driven by increasing demand in automation and precision engineering sectors. This growth underscores the need for manufacturers to maintain strict quality control measures throughout their production processes.

Another critical aspect to assess is the manufacturing precision. High-quality Bellows CNC products are typically manufactured using advanced techniques like computer numerical control (CNC) machining, which ensures tight tolerances and consistent dimensions. A study by MarketsandMarkets highlights that products with tolerances within 0.001 inches significantly reduce failure rates in high-stress applications. Furthermore, examining certifications such as ISO 9001 can provide insights into a manufacturer’s commitment to quality management, thereby making it a vital parameter for evaluating potential suppliers. Engaging in these detailed evaluation steps is essential for sourcing the best Bellows CNC products that align with both operational needs and industry standards.

As the demand for precision components increases in various sectors, the innovations in Bellows CNC products are set to reshape the industry in 2023. One of the most notable advancements is the introduction of advanced materials that enhance durability and flexibility. According to a recent market report by ResearchAndMarkets, the global CNC machining market is expected to reach $100 billion by 2025, driven by innovations like these that cater to diverse applications, from aerospace to medical devices.

Another exciting trend is the integration of smart technology in Bellows CNC products, which allows for improved monitoring and automation during the manufacturing process. This is expected to contribute significantly to efficiency and accuracy, as highlighted in a study by Grand View Research, which estimates that smart manufacturing technologies could reduce production costs by up to 30% by 2025. These top innovations not only meet the evolving needs of manufacturers but also set new benchmarks for operational excellence in the CNC machining landscape.