- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

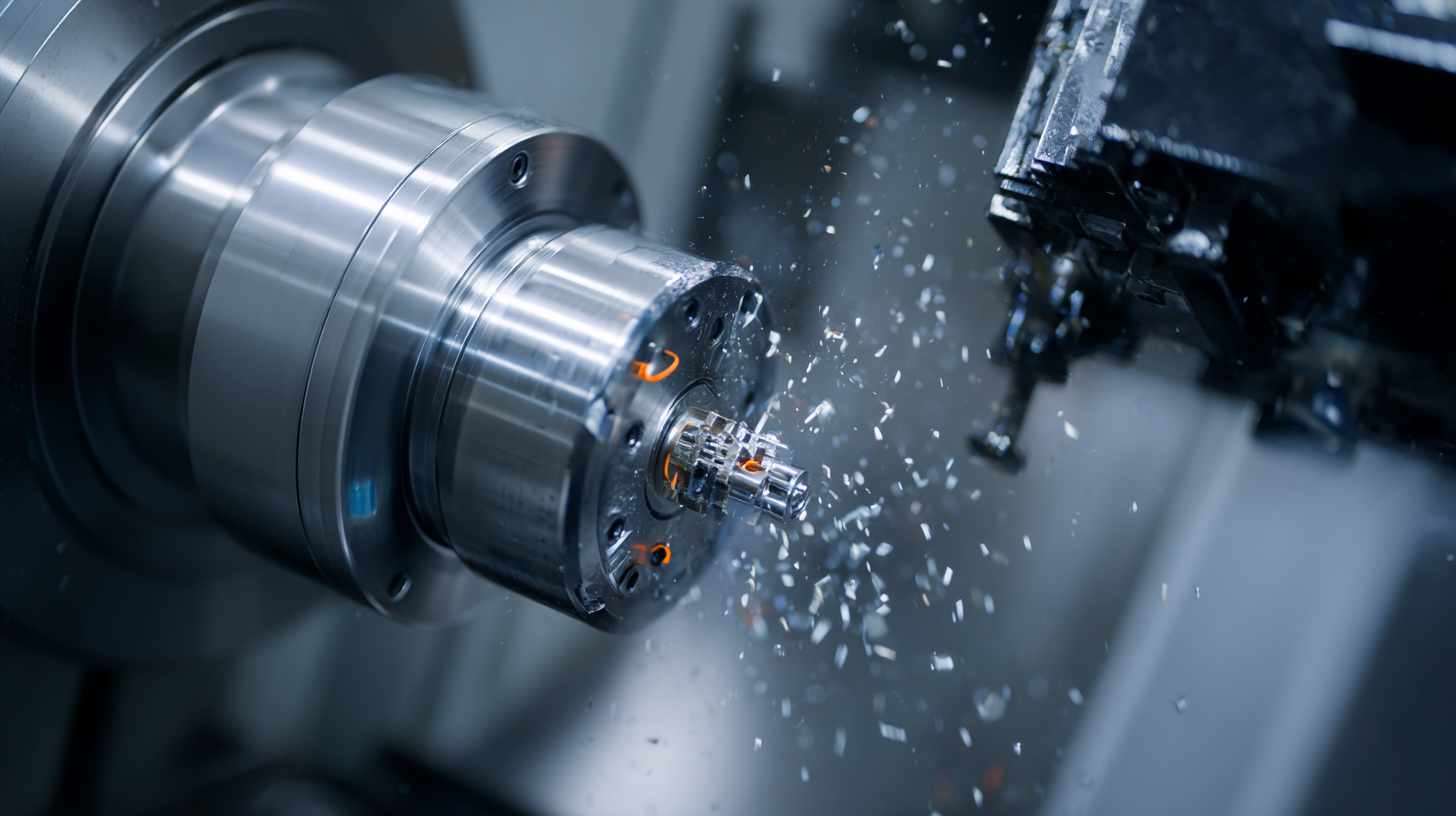

In the realm of modern manufacturing, the significance of CNC inserts cannot be overstated. These cutting tools play a pivotal role in enhancing precision and efficiency across various machining processes, as evidenced by a recent report from MarketsandMarkets, estimating that the global CNC machine market is expected to reach $100 billion by 2025, primarily driven by advancements in tooling technologies.

CNC inserts, the key components that enable these machines to achieve unparalleled accuracy, contribute significantly to reducing cycle times and improving surface finishes—critical factors in competitive manufacturing environments. Furthermore, according to a study by Grand View Research, the increasing demand for automation and rapid tooling has further underscored the growing reliance on high-performance CNC inserts, highlighting their essential position in modern manufacturing landscapes. As industries continue to seek ways to enhance productivity, understanding the intricacies and applications of CNC inserts will be crucial for manufacturers aiming to stay ahead in a rapidly evolving market.

CNC inserts, the key components that enable these machines to achieve unparalleled accuracy, contribute significantly to reducing cycle times and improving surface finishes—critical factors in competitive manufacturing environments. Furthermore, according to a study by Grand View Research, the increasing demand for automation and rapid tooling has further underscored the growing reliance on high-performance CNC inserts, highlighting their essential position in modern manufacturing landscapes. As industries continue to seek ways to enhance productivity, understanding the intricacies and applications of CNC inserts will be crucial for manufacturers aiming to stay ahead in a rapidly evolving market.

The evolution of CNC inserts has played a pivotal role in modern manufacturing techniques. Initially, inserts were rudimentary and limited in functionality; however, over the years, advancements in materials and cutting-edge technologies have transformed them into sophisticated tools. Today’s CNC inserts are crafted from high-performance materials such as carbide and cermet, which enhance durability and optimize cutting efficiency. This evolution not only increases productivity but also reduces downtime due to wear and tear.

Moreover, the adaptation of advanced coatings has significantly improved the performance of CNC inserts. Techniques like PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) have allowed manufacturers to create inserts that can withstand higher temperatures and extend tool life. The development of geometry design has also been revolutionary; innovative shapes and edge configurations are tailored to specific machining needs, enabling precision in complex operations. As manufacturers continue to adopt these advanced CNC inserts, the industry moves closer to achieving higher standards of efficiency and precision in production processes.

CNC inserts have become a cornerstone of modern precision machining, offering a multitude of benefits that enhance productivity and product quality. One significant advantage is their ability to provide superior cutting performance. Crafted from high-quality materials like carbide, these inserts are designed to withstand high temperatures and resist wear, ensuring longer tool life and less frequent replacements. This durability not only streamlines operations but also reduces costs associated with downtime and tool management.

Another compelling benefit of CNC inserts is their versatility. Available in various shapes and sizes, they can be tailored to suit different machining applications, from turning and milling to drilling. This flexibility allows manufacturers to switch inserts quickly to adapt to changing production needs, optimizing workflows and reducing lead times. Additionally, the precision of CNC inserts contributes to tighter tolerances in machined parts, which is essential in industries such as aerospace and automotive where accuracy is paramount. By leveraging the advantages of CNC inserts, manufacturers can achieve greater efficiency and consistency in their machining processes.

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Improved Precision | CNC inserts provide high accuracy in machining operations. | Increased product quality and reduced rework rate. |

| Cost Efficiency | Longer tool life reduces the frequency of insert changes. | Lower manufacturing costs and enhanced productivity. |

| Versatility | CNC inserts can be used for various materials and operations. | Ability to adapt to different production needs and materials. |

| Enhanced Surface Finish | CNC inserts provide a finer finish compared to traditional methods. | Reduced need for secondary finishing processes. |

| Reduced Machining Time | Faster cutting speeds achievable with advanced materials. | Improved efficiency and shorter lead times for products. |

CNC inserts are essential components in modern manufacturing, enabling precise and efficient machining across various industries. These inserts come in different types and geometries, each tailored for specific applications such as milling, turning, and boring. For instance, carbide inserts are widely used for their durability and ability to withstand high temperatures, making them ideal for high-speed machining. Additionally, inserts with specific coatings can enhance performance by reducing wear and improving surface finish.

CNC inserts are essential components in modern manufacturing, enabling precise and efficient machining across various industries. These inserts come in different types and geometries, each tailored for specific applications such as milling, turning, and boring. For instance, carbide inserts are widely used for their durability and ability to withstand high temperatures, making them ideal for high-speed machining. Additionally, inserts with specific coatings can enhance performance by reducing wear and improving surface finish.

In applications ranging from automotive to aerospace, the versatility of CNC inserts is evident. Indexable milling cutters have gained significant traction, with a projected market growth from USD 5.2 billion in 2025 to USD 9.6 billion by 2035. This surge reflects the increasing demand for effective and adaptable cutting tools that can handle both roughing and finishing tasks seamlessly. By utilizing tailor-made inserts, manufacturers can optimize production efficiency and maintain high standards of quality, demonstrating the critical role of CNC inserts in modern production environments.

When selecting CNC inserts for your project, it is crucial to consider several key factors that can significantly impact machining performance. One of the primary aspects to evaluate is the material compatibility of the insert. Different materials—such as steel, aluminum, or composites—require specific insert types to maximize cutting efficiency and tool life. For instance, carbides may be more suitable for harder materials, while coated inserts can enhance performance in high-speed applications.

Another important consideration is the geometry of the insert. Inserts are designed with various shapes and angles that influence cutting dynamics, chip formation, and surface finishes. When choosing an insert, assess the requirements of your project, such as whether you need a sharper point for precise drilling or a robust design for aggressive milling tasks.

Tips: Always consult the manufacturer's recommendations to determine the best insert geometry for your machining operation. Additionally, if you're uncertain about your options, conducting a few test runs with different inserts can provide insightful data that helps refine your selection. Remember, the right CNC insert can lead to improved productivity and reduced costs in the long run, making your choice all the more significant.

As the manufacturing landscape evolves, so does the technology surrounding CNC inserts. According to a recent report by MarketsandMarkets, the global CNC tools market is projected to reach $15 billion by 2025, driven by increasing automation in manufacturing and the rise of Industry 4.0. Innovations in CNC insert technology include the development of advanced materials such as ceramics and composite inserts that enhance tool life and reduce production costs. These advancements enable manufacturers to achieve higher precision and efficiency, addressing the growing demand for complex components in sectors like aerospace and automotive.

Tip: When selecting CNC inserts for your projects, always consider the material being machined and the specific application to improve tool performance and longevity.

Looking towards the future, we can expect significant trends in the customization of CNC inserts. With the integration of artificial intelligence and machine learning into production processes, manufacturers can achieve a more tailored approach to insert design. This will not only improve machining efficiency but also enable the production of inserts that are specifically optimized for unique applications. A report by Grand View Research indicates that personalized manufacturing solutions are set to grow by over 25% annually in the coming years, underscoring the importance of adapting to these technological shifts.

Tip: Stay updated with the latest advancements in CNC insert technology by attending industry trade shows and subscribing to relevant manufacturing journals to gain insights on emerging trends.