- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

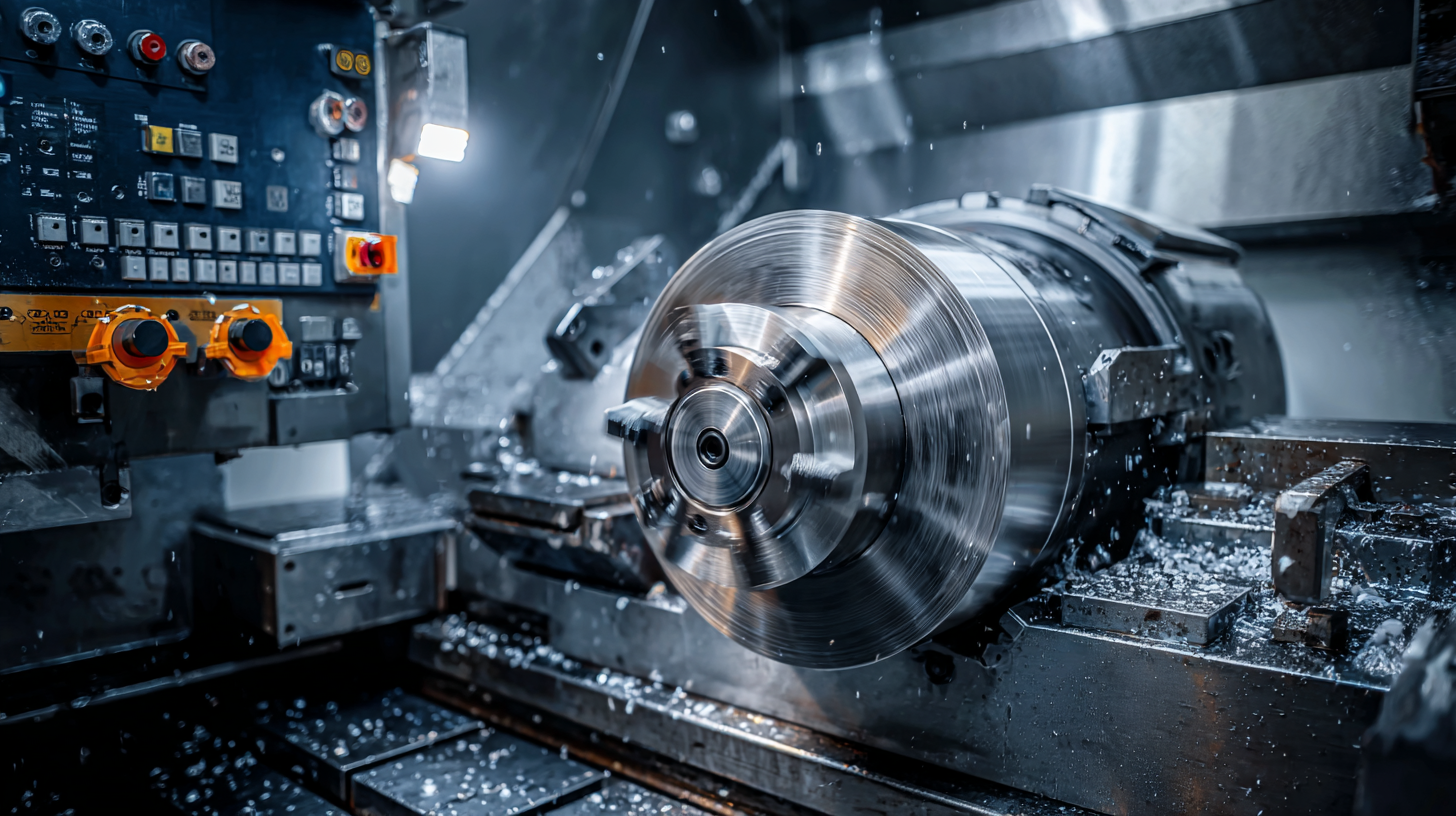

In 2023, the manufacturing landscape is undergoing a significant transformation, largely driven by advancements in technology and precision engineering. Central to this evolution are CNC lathes, which are increasingly celebrated for their ability to enhance accuracy, efficiency, and customization in production processes. According to a recent report by Markets and Markets, the global CNC machine market is projected to grow from $71 billion in 2020 to over $100 billion by 2026, indicating a compound annual growth rate (CAGR) of 6.54%. This growth reflects the rising demand for automation and the capability of CNC lathes to produce complex parts with minimal human intervention. As industries across the board embrace these innovations, understanding how to effectively utilize CNC lathes will be crucial for manufacturers looking to stay competitive in an ever-evolving market.

In 2023, the evolution of CNC lathe technology marks a pivotal moment in manufacturing, demonstrating significant advancements that highlight its role in enhancing productivity across various industries. As per recent reports, the global market for CNC machines is projected to reach an impressive $20 billion by 2030, driven predominantly by sectors such as aerospace, automotive, and renewable energy. This surge illustrates not only the growing demand for precision machining but also underscores the shift toward more sophisticated manufacturing processes.

China is at the forefront of this transformation, emerging as a leading innovator in advanced manufacturing technologies. With a substantial investment in innovation capabilities through its universities and domestic companies, China is set to revolutionize its CNC machines market. The adoption of digital manufacturing technologies is also gaining traction, pushing manufacturers to embrace CNC lathes that offer improved efficiency and accuracy. Events like SOUTHTEC 2023 further showcase these trends, bringing together global suppliers and equipment builders to demonstrate the latest technological solutions tailored for modern manufacturing challenges. These innovations are reshaping not just production lines, but also the very foundation of how industries operate in a rapidly evolving economic landscape.

China is at the forefront of this transformation, emerging as a leading innovator in advanced manufacturing technologies. With a substantial investment in innovation capabilities through its universities and domestic companies, China is set to revolutionize its CNC machines market. The adoption of digital manufacturing technologies is also gaining traction, pushing manufacturers to embrace CNC lathes that offer improved efficiency and accuracy. Events like SOUTHTEC 2023 further showcase these trends, bringing together global suppliers and equipment builders to demonstrate the latest technological solutions tailored for modern manufacturing challenges. These innovations are reshaping not just production lines, but also the very foundation of how industries operate in a rapidly evolving economic landscape.

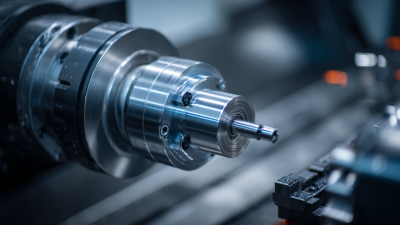

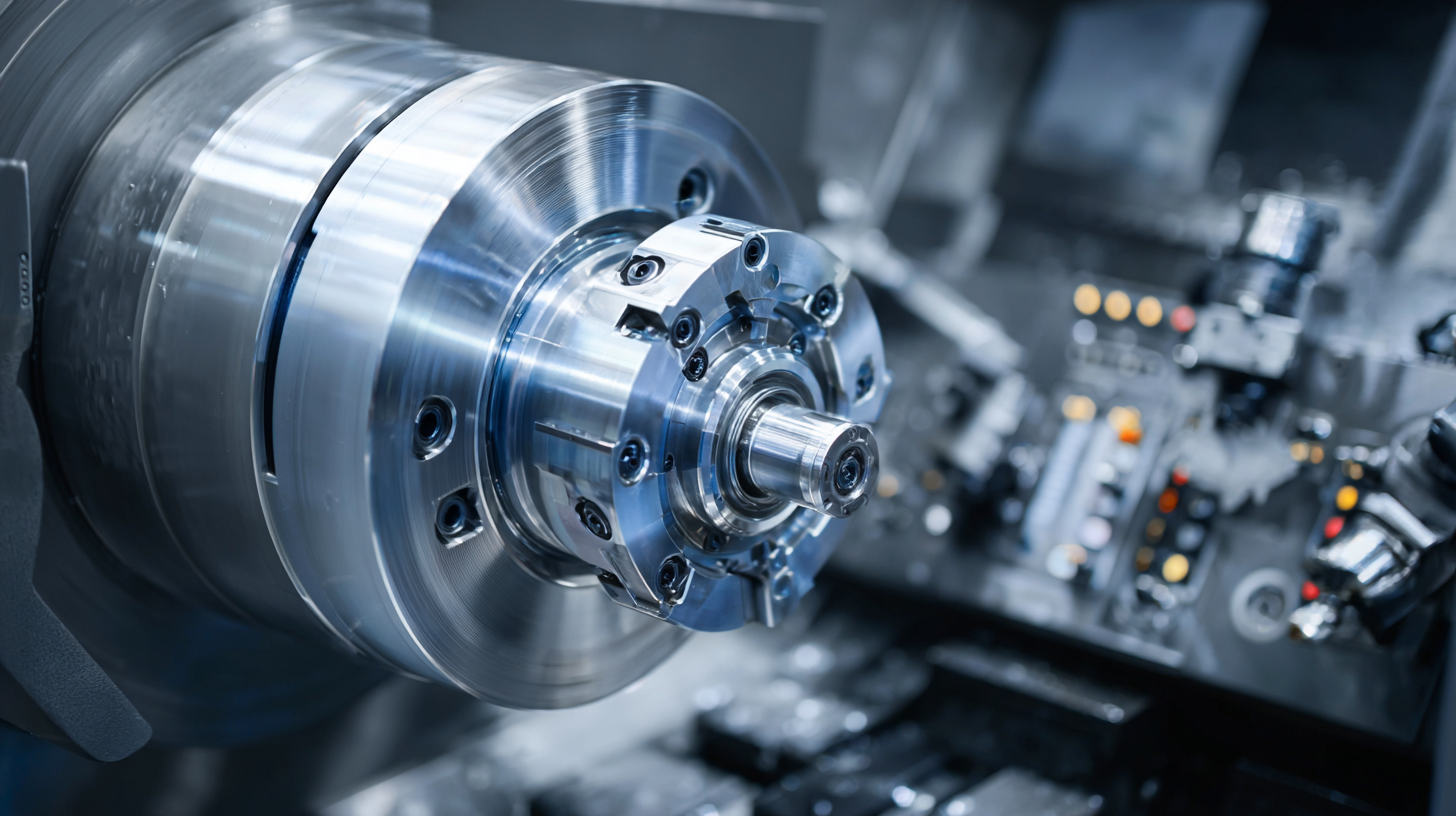

CNC lathes have emerged as a game-changer in modern manufacturing, offering unparalleled precision and efficiency. One of the key advantages of CNC lathes is their ability to produce complex geometries with extreme accuracy. This level of precision not only reduces material waste but also ensures that parts are manufactured to the exact specifications required, which is especially critical in industries like aerospace and automotive.

Tips: When integrating CNC lathes into your production process, consider investing in training for your operators. Skilled personnel can significantly enhance the capabilities of your CNC machinery, leading to improved output quality and time savings.

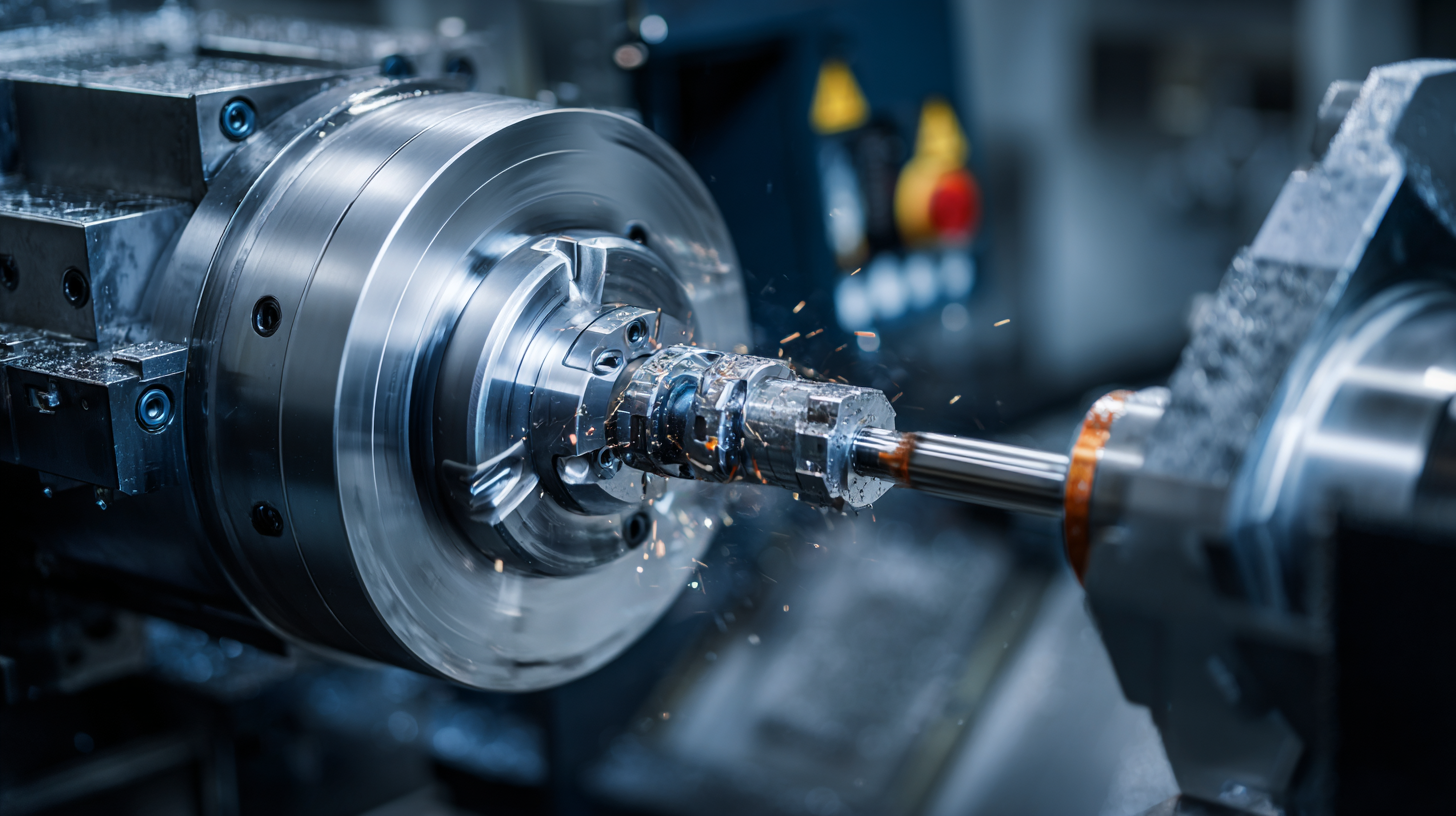

Another advantage of CNC lathes is their automation capabilities, which streamline production workflows. By automating repetitive tasks, manufacturers can free up skilled workers to focus on more complex operations, thereby enhancing overall productivity. Additionally, CNC lathes can be programmed for continuous operation, reducing downtime and maximizing output.

Tips: Regular maintenance of CNC lathes is crucial for sustained performance. Implementing a scheduled maintenance plan can prevent costly breakdowns and prolong the life of your equipment, ensuring your operations remain smooth and efficient.

| Advantage | Description | Impact on Manufacturing | Example Applications |

|---|---|---|---|

| High Precision | CNC lathes offer high precision machining with minimal tolerances. | Reduces waste and ensures quality control. | Aerospace components, medical devices |

| Automation | CNC lathes can be programmed for repeatable manufacturing processes. | Increases production speed and consistency. | Mass production of parts, automotive components |

| Versatility | Capable of producing complex geometries and a variety of materials. | Allows for varied product lines without major downtime. | Custom tooling, electronics housings |

| Flexible Production | Easily reprogrammable for different tasks and products. | Facilitates quick changes in production to meet demand. | Prototype development, short-run manufacturing |

| Reduced Labor Costs | Less manual intervention is required for operation. | Lower overall labor costs while increasing output. | High-volume production lines |

The integration of Internet of Things (IoT) and artificial intelligence (AI) is profoundly reshaping the landscape of CNC machining, heralding a new era of smart manufacturing. By embedding IoT sensors into CNC lathes, manufacturers gain real-time data on machine performance, tooling conditions, and even product quality. This connectivity enables predictive maintenance, significantly reducing downtime and enhancing productivity. As machines become more "aware" through data collection and analysis, the operational efficiency of CNC machining is revolutionized, paving the way for highly optimized production processes.

Moreover, AI plays a pivotal role in automating decision-making within manufacturing environments. From optimizing machining parameters to predicting defects in the production line, AI algorithms analyze vast amounts of data, driving enhancements in accuracy and precision. This smart approach not only minimizes human error but also empowers engineers to focus on innovation rather than routine problem-solving. As the manufacturing sector accelerates towards Industry 4.0, the harmonious integration of IoT and AI stands out as a key driver in crafting a future where CNC machining is smarter, faster, and more efficient than ever before.

CNC lathes are at the forefront of transformative industrial processes, enabling manufacturers to achieve unprecedented levels of precision and efficiency. In the automotive sector, companies like Ford have adopted CNC lathes to optimize their production lines. By transitioning to computer numerical control, they not only reduce waste but also enhance the speed of production. This approach allows for intricate designs and specifications to be consistently met, resulting in superior quality components with minimal human intervention.

In the aerospace industry, Boeing exemplifies the advantages of CNC lathe technology through its implementation in creating lightweight yet robust components. CNC lathes facilitate complex machining operations with a high degree of accuracy, crucial for parts that must withstand extreme conditions. By utilizing this technology, Boeing has significantly shortened lead times while ensuring compliance with rigorous safety standards. These case studies illustrate how CNC lathes are not merely tools but pillars of modern manufacturing, driving innovation and efficiency across a range of industries.

The adoption of CNC lathes in manufacturing has become increasingly prevalent in 2023, driven by the demands for precision, efficiency, and adaptability. Reports indicate that industries utilizing CNC technology have experienced productivity increases of up to 30%, showcasing how these advanced machines can optimize production workflows. As manufacturers strive to stay competitive, the integration of CNC lathes not only reduces lead times but also enhances product quality, allowing for complex designs that were previously difficult to achieve.

However, the road to widespread CNC lathe adoption is not without its challenges. Many companies encounter obstacles related to workforce training and the initial capital investment required for these advanced machines. While the benefits are clear, a study indicates that nearly 40% of manufacturers hesitate to invest in CNC technology due to concerns about return on investment and the adaptability of their existing workforce. Innovators within the industry are addressing these challenges through educational programs and financing options tailored to ease the transition to digital manufacturing technologies, particularly in regions such as China, where a surge in technological capabilities has positioned the nation as a leader in advanced manufacturing solutions.

This chart illustrates the adoption rates of CNC lathes across various industries in 2023, highlighting the growing significance of these machines in enhancing manufacturing precision and efficiency.