- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

The manufacturing sector is constantly evolving, with innovative technologies and strategies emerging to meet the demands of global buyers. Among these advancements, Bellows CNC systems have garnered significant attention due to their precision and versatility in various applications, from robotics to aerospace. According to a recent report by MarketsandMarkets, the CNC machine market is expected to reach USD 100.2 billion by 2025, driven by the increasing adoption of automation in manufacturing processes. However, as enterprises seek to optimize production efficiency and reduce costs, exploring alternative solutions to standard Bellows CNC systems becomes imperative.

This blog delves into top strategies for global buyers, highlighting innovative alternatives that can enhance functionality and performance while addressing specific industry needs. As we navigate this dynamic landscape, understanding these alternatives will empower decision-makers to make informed choices that align with contemporary manufacturing demands.

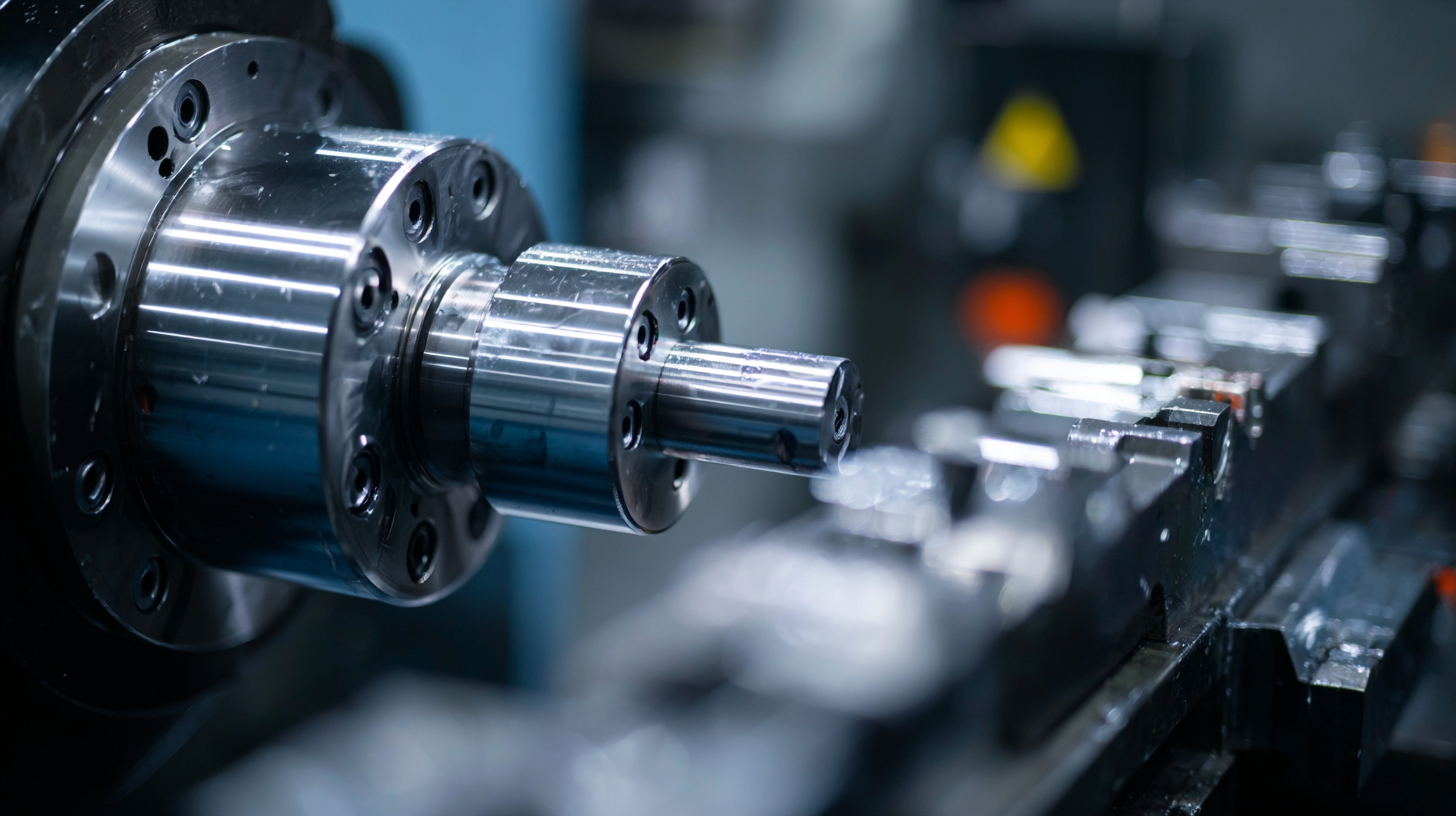

Bellows play a crucial role in various CNC (Computer Numerical Control) applications, serving as protective covers and enhancing the precision and lifespan of the equipment. According to a recent report from MarketsandMarkets, the CNC machine market is projected to reach $100 billion by 2026, with a significant contribution expected from advanced bellows systems. These components help prevent debris, coolant, and other contaminants from damaging the machine's sensitive parts, thus maintaining optimal performance and reducing maintenance costs.

In addition to their protective capabilities, bellows contribute to the flexibility and movement of CNC systems. They accommodate the expansion and contraction of moving parts, providing a seamless operation while maintaining tight tolerances. A study by Grand View Research highlights that the demand for customizable bellows is on the rise, with the global bellows market estimated to expand at a CAGR of 5.6% through 2025. This trend is driven by industries seeking innovative solutions for complex machining processes, ensuring that CNC machinery remains efficient and accurate over time.

When searching for reliable alternatives to the Best Bellows CNC, several key factors should guide global buyers. First and foremost, assessing the material quality is crucial. According to a 2022 market report by Grand View Research, high-quality materials can enhance the performance and durability of CNC systems. Buyers should prioritize options that utilize robust materials like stainless steel or reinforced polymers, which can withstand varying operational conditions and extend the machine's lifespan.

Another important consideration is the technological compatibility of alternative CNC systems. A survey by TechSci Research indicated that 65% of manufacturing firms now prefer CNC machines that integrate seamlessly with Industry 4.0 technologies. This integration allows for better data analysis and process optimization. Ensuring that the chosen alternative has the capability to connect with existing software and hardware can significantly enhance operational efficiency and reduce downtime.

Lastly, cost-effectiveness remains a pivotal factor. A report from Mordor Intelligence revealed that while initial investment costs for CNC machines can vary widely, cheaper alternatives do not always mean lower performance. Buyers should conduct a comprehensive total cost of ownership analysis, considering maintenance, energy consumption, and the potential for upgradability. This approach will help ensure that the selected CNC system not only meets immediate needs but also supports long-term operational goals.

This chart illustrates key factors to consider when exploring innovative alternatives to best bellows CNC options. The data represents assessments of various alternative products based on criteria such as material durability, cost efficiency, customization options, delivery time, and customer support.

In the realm of CNC manufacturing, innovative materials and advanced technologies are reshaping performance metrics, driving productivity to unprecedented heights across various industries. These enhancements stem from the integration of digital manufacturing technologies that not only streamline processes but also improve precision and efficiency. As global buyers seek alternatives to traditional solutions like best bellows CNC systems, the emergence of cutting-edge materials such as composites and smart alloys presents a compelling case for increased adaptability and longevity in CNC applications.

Moreover, the revolution in gear technology highlights the importance of advanced manufacturing processes in achieving superior product performance. The seamless incorporation of nanotechnology in material design is enabling the manipulation of materials at atomic and molecular levels, leading to the development of gears that are not only lighter and stronger but also more efficient. This trend towards digital integration and the exploration of stimuli-responsive materials further illuminates the path for global buyers looking to harness the transformative potential of modern CNC technology in their operations. The innovations within this field promise to unlock new opportunities for sustainable growth and enhanced capabilities.

In the realm of CNC machining, particularly for global buyers, exploring alternatives to Best Bellows CNC solutions is essential for staying competitive and efficient. Various innovative technologies and brands have emerged, promising not only precision but also cost-effectiveness and enhanced functionality. A comparative analysis of these alternatives reveals important insights into features, performance, and customer satisfaction. For instance, buyers can benefit from evaluating options that prioritize scalability and integration with existing systems, which can significantly optimize manufacturing processes.

In the realm of CNC machining, particularly for global buyers, exploring alternatives to Best Bellows CNC solutions is essential for staying competitive and efficient. Various innovative technologies and brands have emerged, promising not only precision but also cost-effectiveness and enhanced functionality. A comparative analysis of these alternatives reveals important insights into features, performance, and customer satisfaction. For instance, buyers can benefit from evaluating options that prioritize scalability and integration with existing systems, which can significantly optimize manufacturing processes.

Additionally, the landscape of CNC solutions is rapidly evolving, much like the advancements seen in other sectors, such as energy storage and cloud computing. By examining alternatives through a lens similar to that used for comparing the best cloud storage services or energy technologies, global buyers can make informed decisions. This approach emphasizes the importance of adaptability in selecting CNC solutions that not only meet current needs but also anticipate future industry developments. As trends shift, it's crucial for businesses to remain agile, ensuring that their manufacturing practices align with emerging technologies and market demands.

The global market for CNC bellows alternatives is evolving rapidly, reflecting changing preferences among manufacturers and buyers. According to recent industry reports, the global woodworking machinery market is projected to expand from $5.23 billion in 2025 to $7.88 billion by 2032, demonstrating a robust compound annual growth rate (CAGR) of 6.0%. This growth underscores a shift toward innovative solutions, including alternatives to traditional CNC bellows systems, as companies strive for greater efficiency and sustainability.

In the automotive sector, the landscape is similarly dynamic. The automotive manufacturing equipment market is witnessing notable trends, with CNC machines, among other equipment types, being pivotal for manufacturers looking to enhance production capabilities. It is essential for global buyers to stay updated on these trends to make informed purchasing decisions.

Tips:

1. Explore various CNC bellows alternatives to find solutions that align with your production goals and sustainability practices.

2. Keep an eye on market forecasts and industry reports to ensure you’re leveraging the most advanced technology available.

3. Engage with suppliers who offer innovative solutions that can improve operational efficiency and reduce costs.