- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

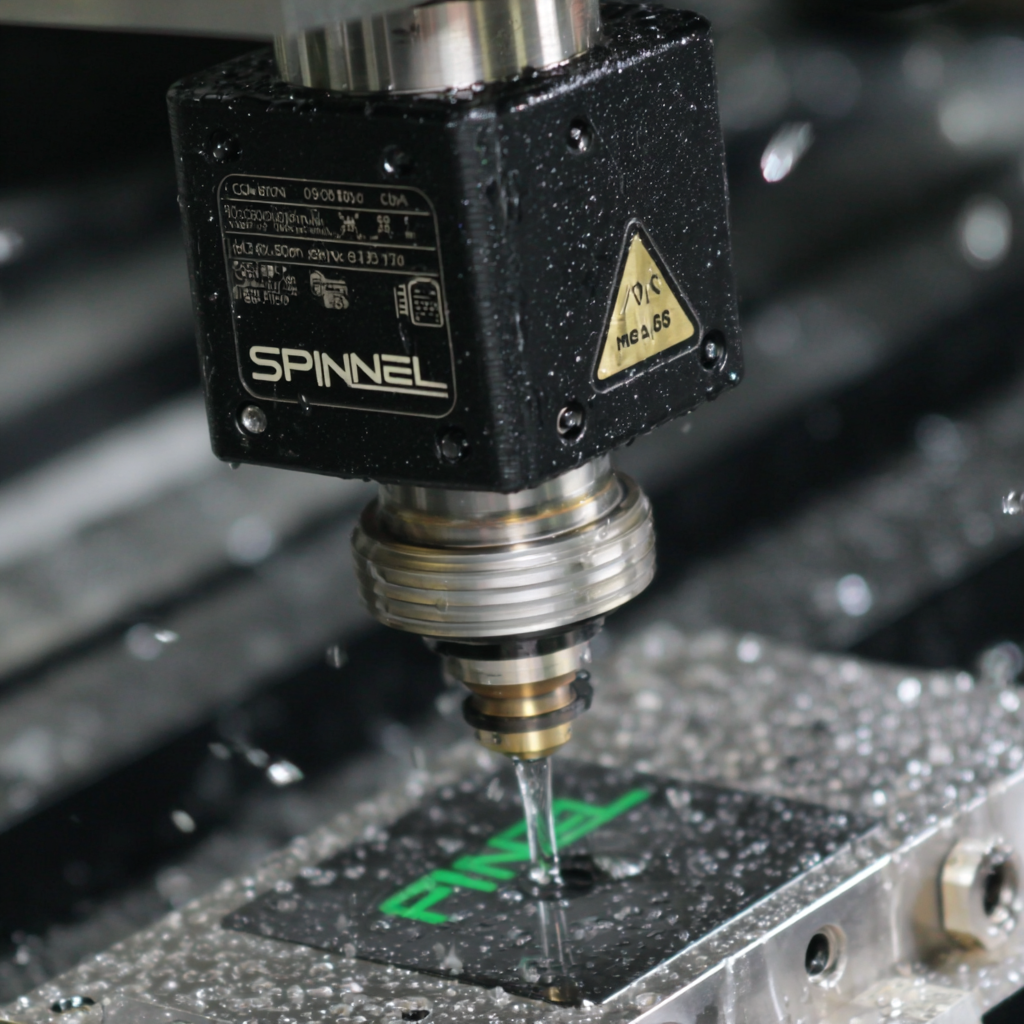

The rise of Spindel Cnc machines has revolutionized the manufacturing and machining industries, providing users with precision and efficiency previously unattainable. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117 billion by 2026, driven largely by advancements in technology and increasing demand for automation.

However, users often encounter common challenges when operating these sophisticated machines. Issues such as software compatibility, maintenance difficulties, and the steep learning curve associated with integrating Spindel Cnc systems into existing workflows can hinder productivity. Understanding these challenges is crucial for users aiming to leverage the full potential of their Spindel Cnc machines, ensuring not only operational efficiency but also a solid return on investment in an increasingly competitive landscape.

When selecting and using spindle CNC machines, users often encounter a variety of challenges that can impact both efficiency and production quality. One of the primary issues is the complexity of integration with existing systems. According to a report by the International Society of Automation, nearly 30% of manufacturers experience integration difficulties when incorporating new CNC technologies into their workflows. This not only affects the initial setup process but also leads to extended training periods for personnel.

Another common challenge lies in the variability of spindle performance under different operational conditions. A study by Manufacturing Engineering Journal indicates that nearly 25% of users report inconsistent machining results due to spindle speed fluctuations and thermal expansion. These issues contribute to decreased accuracy and increased scrap rates, ultimately affecting the bottom line. Addressing these challenges through careful selection of machine specifications and comprehensive training programs can help users avoid common pitfalls and enhance overall machining productivity.

When it comes to CNC machining, spindle speed is a critical factor that significantly influences both machining efficiency and the quality of finished parts. A higher spindle speed can lead to faster material removal rates, which enhances productivity and reduces manufacturing time. However, pushing the spindle speed too high can also introduce challenges, such as increased heat generation and potential tool wear, which can ultimately affect the integrity of the machined material.

Moreover, the type of material being processed plays a pivotal role in determining optimal spindle speed. For hard materials, slower speeds may be required to ensure precision and avoid damaging the tools. Conversely, softer materials can often handle higher speeds without compromising quality. Striking the right balance between speed and material properties is essential for achieving desirable results in CNC machining. Engineers and operators must carefully analyze these factors to optimize performance and enhance the overall quality of the machined components.

Maintaining optimal performance in CNC machines, particularly high-quality spindle CNC machines, is crucial for any operator seeking efficiency and precision in machining processes. Regular maintenance is not just about keeping the machines running; it also ensures that the intricate parts operate smoothly and extends the lifespan of the equipment. Users must develop a systematic maintenance schedule that includes routine checks on key components such as spindles, bearings, and cooling systems. Neglecting these aspects can lead to sudden breakdowns or diminished performance, which could incur substantial costs and delays.

Moreover, understanding the specific maintenance needs of spindle CNC machines can significantly impact productivity. Operators should be trained to recognize signs of wear and abnormal performance, such as unusual noises or vibrations, which may indicate underlying issues. Implementing preventive maintenance procedures—such as regular lubrication, calibration, and the inspection of electrical components—can help identify problems before they escalate. With the right approach to maintenance, users can not only keep their CNC machines in peak condition but also enhance the quality of their output, resulting in greater customer satisfaction and a competitive edge in the industry.

When it comes to operating the best spindel CNC machines, one common challenge that users face is software compatibility. The effectiveness of a CNC machine is often heavily reliant on the software that drives it. Users frequently encounter situations where their chosen design software does not seamlessly integrate with the CNC machine’s control system. This misalignment can lead to inefficient workflows, increased errors, and ultimately, unsatisfactory results.

Investing in CNC machines with software that supports various file formats and platforms can significantly enhance the user experience. A compatible software environment allows for smoother communication between design and machining processes, minimizing glitches that can arise from incompatible data transfers. Furthermore, manufacturers who prioritize software compatibility often provide updates and support, ensuring that users can adapt to new technologies and maintain optimal performance. Consequently, understanding the importance of software compatibility is crucial for anyone looking to maximize the potential of their CNC machinery.

| Challenge | Impact on User Experience | Software Compatibility Issues | Recommended Solutions |

|---|---|---|---|

| Limited Software Options | Decreased productivity and frustration | Incompatibility with existing CAD/CAM software | Invest in versatile software that supports multiple formats |

| Lack of User Support | Difficulty in troubleshooting issues | Software updates may not be user-friendly | Engage with community forums and tech support |

| Installation Complications | Delays in project timelines | Configuration mismatches during setup | Follow detailed installation guides or seek professional help |

| Performance Issues | Lower efficiency and increased costs | Outdated software versions | Regularly update software to the latest version |

| Complex Interface | Steep learning curve for new users | Incompatibility with common operating systems | Opt for user-friendly interfaces and training programs |

One of the most significant challenges faced by operators of spindle CNC machines is the gap in training and skills. Many users may have a basic understanding of CNC operations but lack the in-depth knowledge required for optimal operation and maintenance of these machines. This gap can lead to inefficiencies, machine errors, and ultimately increased operational costs. Organizations must prioritize comprehensive training programs that cover both theoretical knowledge and practical skills to effectively bridge this gap.

Tips for enhancing training effectiveness include the implementation of hands-on workshops that allow operators to interact with spindle CNC machines in a real-world setting. Additionally, pairing less experienced operators with seasoned professionals as mentors can foster skill development through shared knowledge and experience. Regular assessments can also help identify specific areas where additional training is needed, allowing organizations to tailor their programs accordingly.

It's crucial to stay updated with the latest technologies and software related to spindle CNC machining. Encouraging operators to attend industry conferences, seminars, or online courses can significantly enhance their skill set and confidence. By prioritizing continuous learning, organizations can ensure their operators are well-equipped to utilize spindle CNC machines to their fullest potential, enhancing both productivity and quality.