- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

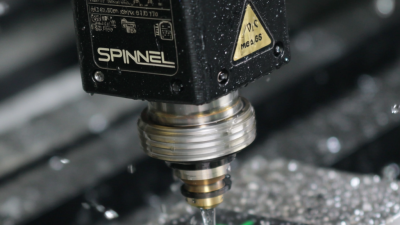

Choosing the right CNC bearings is critical for achieving optimal performance and precision in machining operations. According to a 2022 industry report by MarketsandMarkets, the global CNC machine tools market is expected to reach $100 billion by 2027, driven largely by advancements in technology and increased adoption of automation across various sectors. CNC bearings play a significant role in this growth, as they directly influence the efficiency and longevity of machinery. High-quality bearings can reduce friction, enhance speed, and improve the overall accuracy of machining processes. With numerous options available, understanding the specific requirements of your application is essential for selecting the most suitable CNC bearings. This guide will explore key factors to consider when making your choice, ensuring that your machining needs are met with precision and reliability.

When selecting CNC bearings for specific machining needs, understanding the various types available is crucial. Bearings are fundamental in CNC machinery, impacting precision, accuracy, and the overall efficiency of operations. The most common types include deep groove ball bearings, angular contact bearings, and spherical roller bearings, each serving distinct purposes. For example, deep groove ball bearings are known for their versatility and ability to handle radial and axial loads, making them ideal for a broad range of applications.

Tips: Always consider the lubrication requirements and load capacity when choosing bearings. Bearings with a higher load rating may withstand more stress, thereby extending the machine's lifespan.

Additionally, recent industry reports indicate that maintenance plays a significant role in the longevity and performance of CNC bearings. Implementing regular lubrication schedules and compatibility checks with the machine environment can help to mitigate wear and tear. For example, angular contact bearings excel in high-speed applications, where precision is paramount, especially in assembly lines where accuracy can significantly impact productivity.

Tips: Regularly inspect bearing performance metrics to detect potential issues early and avoid costly downtimes.

When selecting CNC bearings for your machining needs, several key factors should be taken into account to ensure optimal performance and longevity. One essential consideration is the size and type of the bearings, which should align with the specifications of the CNC machine. Additionally, understanding the load capacity and operating conditions, such as speed and temperature, plays a critical role in ensuring the bearings can handle the demands of the machining process.

The global CNC machine market is expected to experience significant growth, with the market size projected to reach $168.6 billion by 2037, driven by a compound annual growth rate (CAGR) of 6.7%. This robust growth underscores the increasing demand for high-quality components, including CNC bearings, that meet the evolving needs of various industries. For instance, the wood processing machinery market alone is predicted to expand from $5.23 billion in 2025 to $7.88 billion by 2032, indicating a CAGR of 6.0%. Selecting the right bearings not only enhances the efficiency of machines but also contributes to maintaining production standards as market demands evolve.

| Bearing Type | Load Capacity (kg) | Speed Rating (RPM) | Material | Temperature Range (°C) | Price Range (USD) |

|---|---|---|---|---|---|

| Ball Bearing | 150 | 12000 | Chrome Steel | -20 to 120 | 10 - 50 |

| Roller Bearing | 300 | 5000 | Stainless Steel | -30 to 150 | 20 - 100 |

| Thrust Bearing | 200 | 3000 | Bronze | -20 to 100 | 30 - 150 |

| Deep Groove Ball Bearing | 100 | 15000 | Carbon Steel | -20 to 120 | 5 - 25 |

| Angular Contact Bearing | 250 | 10000 | Ceramic | -40 to 180 | 50 - 200 |

When selecting CNC bearings, one of the critical factors to consider is their load capacities and speed ratings. Bearings are designed to handle varying loads; therefore, understanding axial and radial load ratings is essential for ensuring longevity and performance. For example, deep groove ball bearings generally offer high speed capabilities and can accommodate both axial and radial loads, making them suitable for several machining applications. According to industry reports, the static load capacity for standard deep groove ball bearings can typically range from 1,000 to over 15,000 newtons, depending on size and material composition.

In recent studies, the performance of advanced materials like polytetrafluoroethylene (PTFE) has been evaluated in bearing applications, particularly regarding wear resistance in conditions involving rolling contact fatigue. Initial testing indicates that PTFE composites exhibit promising results, potentially extending the life of bearings in high-stress environments. Additionally, the incorporation of nanocellulose in polyvinylidene fluoride (PVDF) membranes is showing potential to enhance mechanical properties, further suggesting a trend toward using innovative materials to meet stringent performance requirements in CNC machining. Understanding these advancements, alongside traditional specifications, allows manufacturers to make informed decisions when selecting the appropriate CNC bearings for their specific needs.

When selecting CNC bearings for machining applications, the choice of materials plays a crucial role in ensuring durability and performance. Common materials used for bearings include stainless steel, chrome steel, and ceramic. Stainless steel bearings are highly resistant to corrosion and are ideal for environments exposed to moisture or chemicals. Their durability makes them suitable for general-purpose applications, but they may not perform as well under high-speed conditions compared to chrome steel options.

Chrome steel bearings are popular for their excellent hardness, making them suitable for high-load and high-speed applications. These bearings often provide a good balance of strength and resistance to wear. However, they may require protective coatings to enhance their corrosion resistance in harsher environments. For specialized applications, ceramic bearings offer exceptional resistance to wear and thermal expansion, making them ideal for cutting-edge CNC machining tasks where precision and longevity are paramount. Understanding the specific operating conditions and requirements of your machining needs will guide you in selecting the most appropriate bearing material.

When it comes to CNC machining, the longevity and efficiency of your machinery largely depend on the quality and maintenance of CNC bearings. According to a report by the National Institute of Standards and Technology, improper maintenance can reduce bearing life by up to 30%. To ensure optimal performance, it is crucial to implement a routine maintenance schedule. This includes regular cleaning to remove contaminants, checking for wear and tear, and lubricating bearings as per the manufacturer’s recommendations.

Incorporating high-quality, industry-standard lubricants can significantly extend the lifespan of CNC bearings. The American Society of Mechanical Engineers (ASME) emphasizes that using the right lubricant not only reduces friction but also prevents overheating, which is vital in high-speed applications. Additionally, ensuring that your CNC machine operates within the recommended load limits can decrease the likelihood of premature bearing failure. By following these maintenance tips, you can enhance the operational efficiency of your CNC machinery and reduce long-term costs associated with bearing replacements.