- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Choosing the right CNC parts is crucial for any machining project. The quality and precision of these components heavily influence the final product and overall efficiency. According to a report by IndustryWeek, improper part selection can lead to a 30% increase in production times and costs. This emphasizes the importance of careful consideration in the CNC parts selection process.

Expert John Foster, a leading figure in the CNC industry, once stated, "The right parts make all the difference in achieving the desired outcomes." His insights resonate deeply in a field where accuracy and reliability are paramount. Projects can easily suffer from delays or subpar results if the parts don't meet the required specifications.

While it might be tempting to prioritize cost over quality, a short-term savings approach could lead to significant long-term issues. Every decision, from material choice to compatibility, impacts the project's success. Ultimately, investing time in understanding and selecting the best CNC parts is critical for achieving optimal results and maintaining a competitive edge in the market.

CNC parts play a crucial role in manufacturing. These components determine the quality of the final product. A study from the International Journal of Advanced Manufacturing Technology revealed that poor CNC parts lead to an increase in production errors by 30%. Choosing the right parts is essential. Each component influences precision and durability.

For instance, motors must deliver consistent torque. Inadequate motors can affect machining speed and accuracy. According to a report by MarketsandMarkets, the demand for high-quality CNC parts is projected to grow at a CAGR of 7.89% from 2020 to 2025. This surge highlights the importance of investing in reliable components.

However, not all CNC parts are created equal. Some may look attractive but compromise performance. Users often overlook compatibility. Mismatch between parts can lead to increased downtime, which is costly. Reflecting on these details is critical. The right mix of quality and compatibility will enhance project outcomes.

| CNC Part | Material | Application | Compatibility | Cost ($) |

|---|---|---|---|---|

| Stepper Motor | Steel | Motion Control | Various CNC Mills | 150 |

| CNC Router Bit | Carbide | Woodworking | CNC Routers | 25 |

| Spindle | Aluminum | Metal Machining | CNC Lathes | 400 |

| Control Board | Plastic | Electrical Control | Various CNC Machines | 200 |

| Linear Guide Rail | Steel | Motion System | CNC Mills and Lathes | 100 |

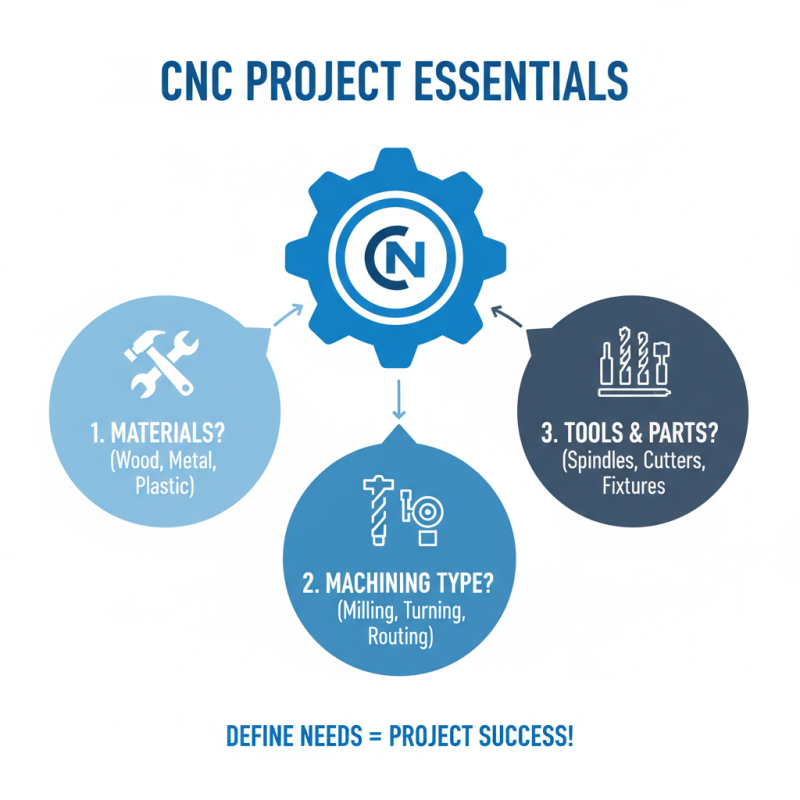

When embarking on a CNC project, understanding your requirements is critical. Each project demands specific features. Ask yourself: What materials will you use? Consider the type of machining needed. Will it be milling, turning, or something else? Each method may require different tools or parts.

Take a closer look at your design specifications. Dimensions matter. Even slight errors can lead to issues. Think about tolerances and finish quality. These factors play a significant role in the final product. If you neglect them, you might face costly redesigns.

Consulting with experts is invaluable. However, remember that what works for one project may not suit another. Each project has its unique challenges and constraints. Reflect on past mistakes and learn from them. Embrace the iterative process of refining your design. It’s all part of evolving as a maker.

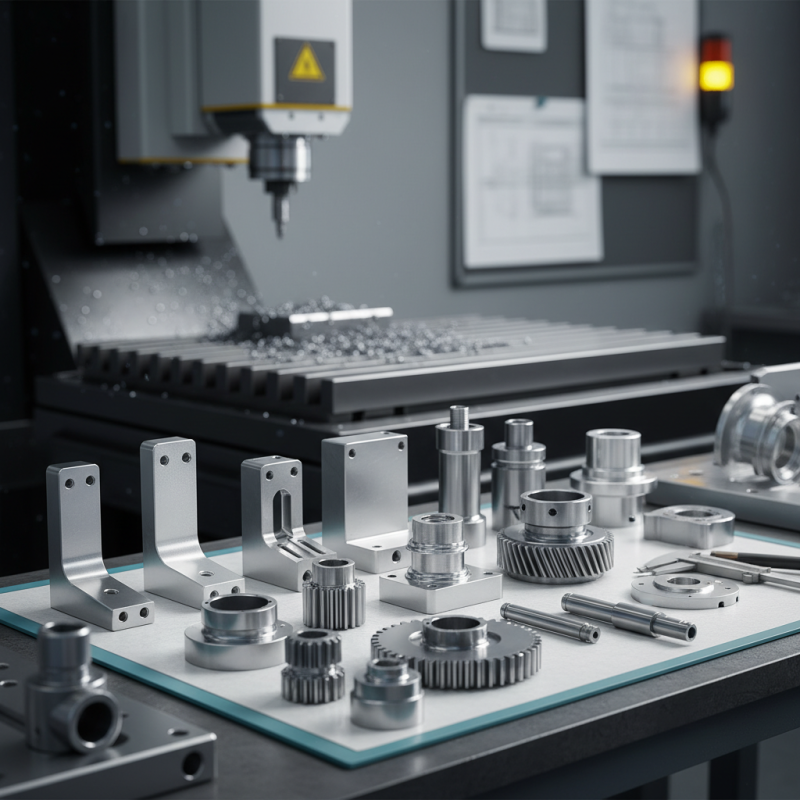

When choosing CNC parts, it’s important to explore the various types available. Each type serves a unique function in the machining process. For instance, there are milling cutters, which remove material through rotary motion. Drill bits help create holes, while end mills can shape intricate profiles. Understanding the differences is crucial for project success.

Consider the material of the CNC parts as well. Carbide tools offer durability but can be more expensive. HSS (High-Speed Steel) tools are cost-effective but may require more frequent replacement. The choice of tool can affect both precision and overall project efficiency. Opting for lower-quality parts might save money upfront but could lead to poor results.

Compatibility is another key factor to evaluate. Not all parts work well with every CNC machine. Misfits can cause operational issues. It's essential to examine specifications closely. Reflecting on previous projects can also help you avoid mistakes. Each experience offers insight into better selection for future tasks.

Choosing the right material for CNC components is crucial. Different projects may demand specific properties, like strength or weight. Metal alloys, such as aluminum or titanium, are prevalent due to their robustness. According to a 2022 industry report, aluminum alloys account for over 40% of CNC applications in aerospace and automotive sectors.

Plastics also hold their ground in CNC machining. They are lightweight and resistant to corrosion. Polycarbonate and nylon are popular choices because of their impact resistance. A study found that 30% of CNC parts used in consumer products are made from plastic materials. However, they may not always withstand high temperatures.

Evaluating each option requires a keen understanding of your project's needs. Sometimes, combining materials could yield better results. A reflective approach can lead to innovative solutions, enhancing durability and performance. Sticking to one material is often too limiting. Consider the complete picture. The right mix will meet your project’s goals while minimizing costs.

When selecting a reliable supplier for CNC parts, consider their credibility. Research their history and customer feedback. A supplier's experience often reflects their reliability. Check for certifications that indicate quality standards. If they lack proper credentials, it may raise concerns.

Communication is crucial. A good supplier should respond promptly to inquiries. They should be willing to provide technical support and guidance. If you encounter delays in their replies, it might indicate a lack of commitment. Request samples to assess the quality of their parts. This hands-on experience can inform your decision.

Price is important, but it isn’t everything. Sometimes, lower prices come with trade-offs like quality. Weigh the cost against the reliability of the supplier. Look beyond numbers and assess overall value. A reliable supplier can save you from future headaches, even if their prices are slightly higher.