- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

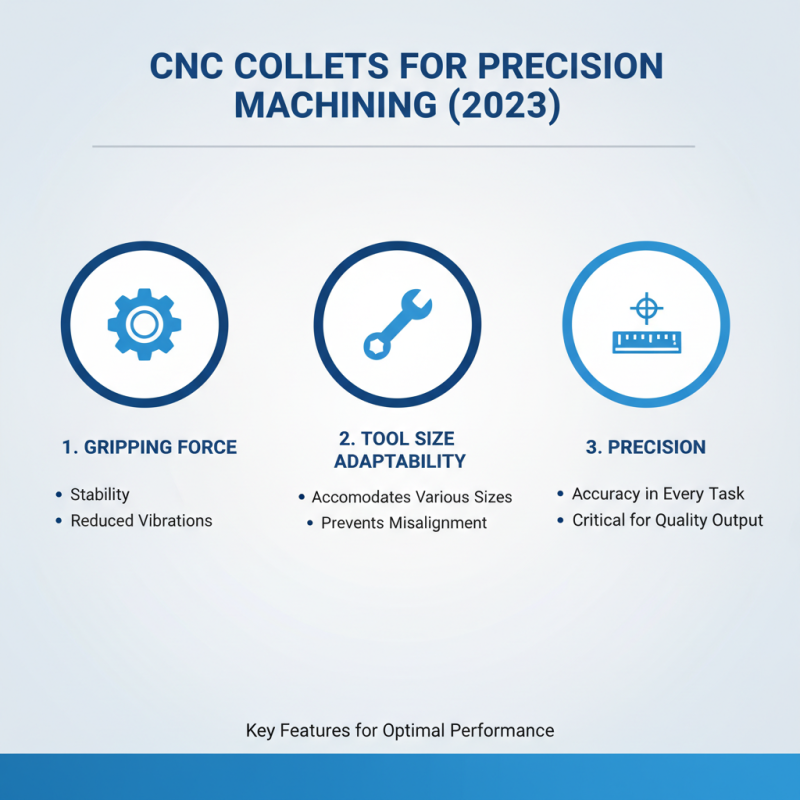

In the world of precision machining, the choice of tools can make or break a project. One of the essential components in this domain is the CNC collet. These small but crucial tools hold the workpiece securely, ensuring accuracy during machining operations. Selecting the right CNC collet can enhance efficiency and improve the overall quality of your work.

2023 brings a variety of CNC collets, each offering unique features and benefits. Some collets excel at gripping smaller materials, while others provide stability for more complex machining tasks. It’s important to understand which collet suits your specific needs. Brands differ in quality and performance, contributing to potential frustrations during usage. Some users report issues with collet sizes and compatibility, leading to costly mistakes.

Choosing the best CNC collet should involve careful consideration. Factors such as material, design, and clamping force play a vital role. A well-chosen collet can lead to finer results and increased productivity. However, with many options available, making a decision can feel overwhelming. Reflect on your own experiences and needs before making a choice. Ultimately, a thoughtful selection can transform your machining process.

CNC collets are critical tools in precision machining. They provide a secure grip on cutting tools, ensuring accurate machining. Studies show that proper collet selection can reduce tool wear by up to 30%. This reduction leads to improved machining efficiency and productivity.

The size and material of collets directly influence their performance. Many manufacturers highlight the importance of using high-carbon steel or hardened alloy materials. They offer better stability under high-speed operations. Yet, not all collets are created equal. Choices made during setup can affect the machining process significantly.

Inaccurate collet choices can result in vibration and chatter. These issues often lead to poor surface finishes and dimensional inaccuracies. A 2022 industry report indicated that nearly 25% of machining errors were linked to improper clamping methods. It’s essential for machinists to evaluate their collet options thoroughly. Choosing the right type helps to maximize tool performance and extend tool life.

When selecting CNC collets for precision work, several factors should be taken into account. The material of the collet is crucial. Steel collets tend to offer durability. However, ceramic collets may provide higher precision in certain applications. Each material has its pros and cons.

Another important factor is the collet size. Ensure your collet fits securely in the spindle. A loose fit can cause vibration. This can lead to inaccuracies in machining. These errors might be subtle but can accumulate over time. Also, consider the gripping range of the collet. Wider gripping ranges provide versatility but may compromise precision.

Check the design of the collet. Some designs allow for easier loading and unloading. This can save time during setups. However, they might not always provide the best grip for delicate work. Remember to evaluate your specific needs. Sometimes, the perfect collet might not exist. Reflect on your experiences. This can lead to better choices in future projects.

When selecting CNC collets for precision machining, understanding the brands and their features is vital. Some manufacturers prioritize material quality. Others focus on innovative designs. The best collets minimize runout and enhance grip. Choosing a reliable collet can significantly improve machining outcomes.

Tips: Always check the collet compatibility with your machine. A mismatched collet can lead to inaccuracies. Regular maintenance is essential. Clean your collets often to ensure they function correctly.

Look for features like heat resistance and clamping force. Certain collets can handle higher temperatures during machining. Others offer superior tool retention, reducing vibration. Evaluate your machining needs carefully. A less expensive collet might perform poorly compared to a reliable one. Don't settle for mediocrity in your tools. Always aim for precision.

When searching for the best CNC collets for precision machining in 2023, it’s crucial to consider various features. The gripping force of each collet is vital. A strong grip ensures stability, reducing vibrations during operations. Collets should accommodate different tool sizes effectively. Misalignment can cause significant issues. Precision matters in every task.

Each option varies in quality and performance. Some collets might not fit certain machines snugly. It's essential to test compatibility before purchase. The material of the collet also influences durability and precision. Steel is usually reliable, but some may prefer aluminum for lighter applications. Adjusting torque is necessary to avoid slippage.

One should reflect on personal machining needs. A collet that works well for one project may not suit another. Understanding the specific requirements can prevent costly mistakes. Users may find that their preferred collet does not work in every situation. Trial and error often leads to better choices over time. Always assess your specific machining demands before making a decision.

When looking for the best CNC collets, user reviews provide valuable insights. Many machinists emphasize precision. They often highlight how different collets affect tool gripping and accuracy. Feedback frequently indicates that choosing the right collet type enhances machining performance significantly. Users have shared experiences about the struggle to achieve consistent results with inferior collets.

Tip: Always consider material quality. High-quality collets resist wear and provide better grip. This can minimize vibrations during machining. Some users notice a marked difference in the finish of their projects when using premium collets.

Feedback from the community shows a variety of preferences. Some favor collets that are easy to install and remove. Others look for designs that offer superior grip strength. However, many users warn that not all collets perform as advertised. It’s essential to read reviews before making a purchase decision.

Tip: Pay attention to the size and fit. An incorrect size can lead to frustration. Users often recommend measuring the shank of tools carefully. This simple step can save time and improve overall outcomes.