- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

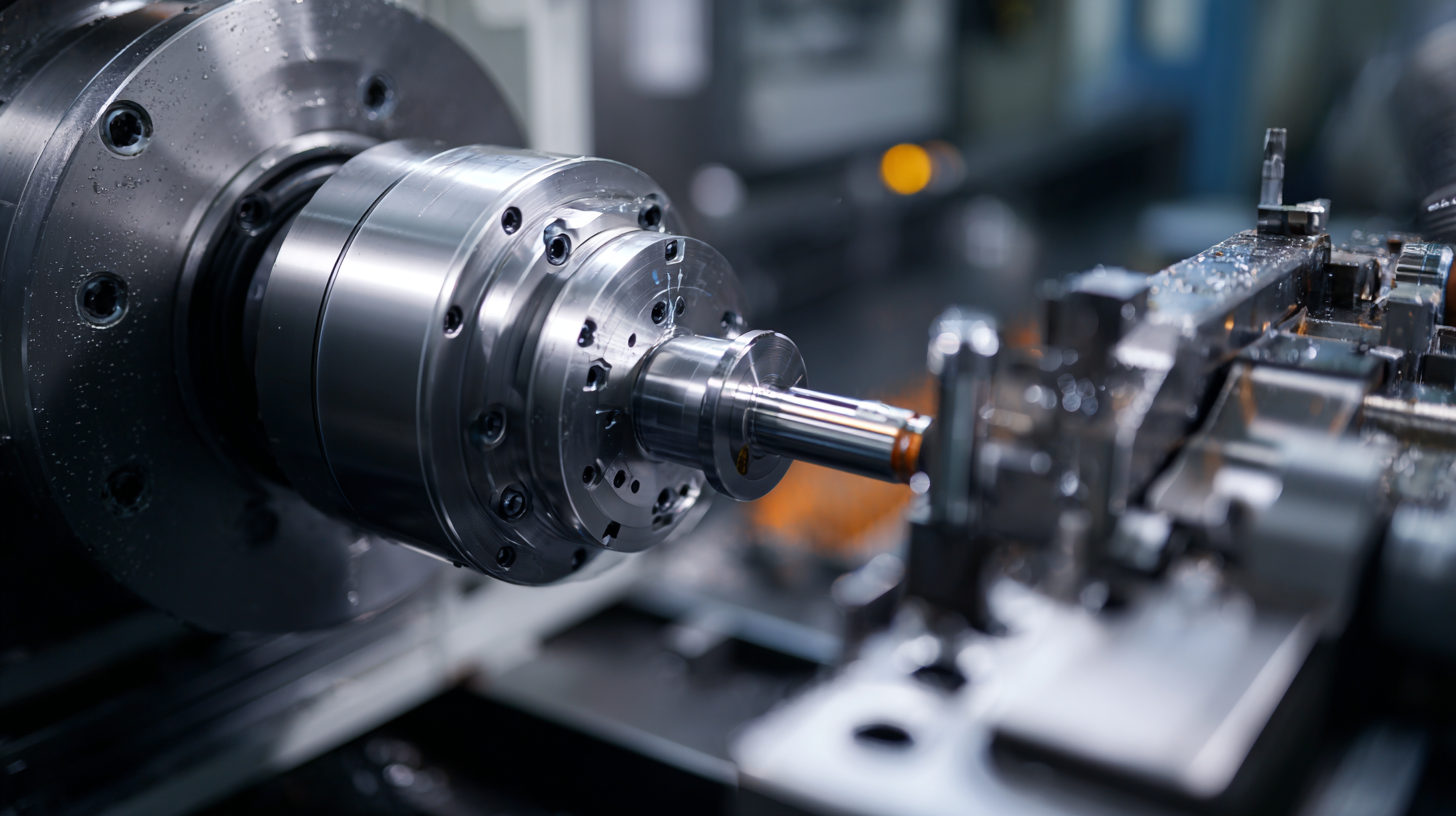

In today's rapidly evolving manufacturing landscape, the integration of advanced technologies has become imperative for businesses looking to stay competitive. One of the standout innovations is Metal CNC (Computer Numerical Control) machining, which offers unparalleled precision and efficiency in production processes. According to a recent report by the Industry Research Institute, the global CNC machine market is projected to reach USD 117.4 billion by 2025, with a significant portion driven by the increasing demand for metalworking applications. The adoption of Metal CNC technology not only enhances the accuracy of complex designs but also reduces lead times, thereby boosting overall productivity. As manufacturers strive to optimize operations and minimize costs, understanding the advantages of selecting the best Metal CNC solutions becomes essential for meeting diverse production needs and achieving long-term business success.

The role of metal CNC machining in modern manufacturing practices has become increasingly crucial as industries strive for precision and efficiency. According to a report by MarketsandMarkets, the CNC machining market is projected to reach $100 billion by 2026, growing at a CAGR of 7.3%. This growth is significantly driven by the rising demand for custom parts and components in sectors such as aerospace, automotive, and healthcare, where precision is non-negotiable.

Metal CNC machining offers unparalleled advantages, including enhanced productivity and reduced waste. A study from the National Institute of Standards and Technology (NIST) reveals that implementing CNC machines can improve production rates by 30-50%, while minimizing material waste through accurate cutting techniques. Furthermore, advancements in CNC technology, such as automation and real-time monitoring, allow manufacturers to achieve higher levels of operational efficiency, ensuring that even complex designs can be produced with high repeatability. By leveraging these capabilities, businesses can not only meet market demands but also push the boundaries of innovation in manufacturing practices.

When it comes to optimizing manufacturing processes, using the best metal CNC machines significantly enhances efficiency and precision. According to a report by the International Federation of Robotics, CNC machines enable manufacturers to achieve a production increase of up to 40% while minimizing waste by nearly 25%. This boost in productivity not only lowers operational costs but also increases output quality. High-quality metal CNC machines can handle intricate designs with tight tolerances, making them ideal for industries such as aerospace and automotive, where precision is paramount.

Moreover, metal CNC machines offer unparalleled repeatability and consistency. Research from the Manufacturing Institute indicates that businesses utilizing advanced CNC technology have seen a reduction in errors by up to 90%. This contributes to a more streamlined production workflow and minimizes the need for manual adjustments, which can be time-consuming and prone to human error. Investing in the best metal CNC machines not only addresses production demands but also aligns with the industry's growing trend toward automation, further securing a competitive edge in the market.

| Feature | Benefit | Impact on Efficiency | Impact on Precision |

|---|---|---|---|

| High-Speed Machining | Reduces production time | Increases throughput | Maintains tight tolerances |

| Advanced Tooling | Enhances tool life | Reduces downtime for tool changes | Improves surface finish |

| Automation Capabilities | Minimizes human error | Streamlines workflows | Ensures consistent quality |

| User-Friendly Interfaces | Easier machine operation | Decreases training time | Reduces operator errors |

| Robust Construction | Increases machine longevity | Less frequent replacements | Consistent accuracy over time |

The CNC (Computer Numerical Control) machinery market is witnessing significant growth as industries pivot towards advanced manufacturing solutions. With a projected market value soaring from USD 116.32 billion in 2025 to USD 182.34 billion by 2034, this growth reflects the increasing demand for high-precision components across various sectors. As emerging technologies and automation shape the landscape of metalworking, companies are incorporating CNC technology to enhance productivity and reduce operational costs. This surge in demand is further amplified by the rise of multi-axis machining centers that cater to complex manufacturing needs.

In tandem with the CNC machinery boom, the global market for metalworking fluids is also on the rise, driven by robust industrial demands and a growing focus on sustainability. As manufacturers seek to improve efficiency and minimize waste, innovative metalworking fluids are becoming essential components of production lines. The integration of AI and advanced manufacturing techniques is poised to redefine product development processes, making it crucial for companies to adopt the best CNC systems tailored to their specific manufacturing objectives. The evolving market dynamics highlight the necessity for businesses to stay ahead of trends shaping the future of CNC metalwork.

When selecting the right metal CNC machine for your business, it’s crucial to consider various factors that align with your manufacturing needs. The advancements in technology have revolutionized CNC machining, enabling businesses to optimize production processes and enhance product quality. This comprehensive guide will help you navigate the essential criteria for choosing the best metal CNC, ensuring that you meet the demands of an evolving market.

Among the key considerations is the type of materials your business works with. Recent developments in the metal industry, such as innovative recycling methods and the emergence of high-value metal production, highlight the importance of versatility in CNC machinery. Look for machines that can efficiently handle different metal types and thicknesses, allowing for greater flexibility in production.

Furthermore, considering the machine’s scalability and safety features is paramount, especially as businesses expand and automation becomes increasingly integrated into manufacturing processes. By focusing on these essential elements, you can make an informed decision that supports your business's growth and productivity goals.

The landscape of metal CNC machining is rapidly evolving, driven by innovative technologies that promise to redefine manufacturing processes. According to a report by Grand View Research, the global CNC machining market is expected to reach USD 100 billion by 2025, growing at a compound annual growth rate (CAGR) of 8.4%. This growth is largely attributed to advancements in automation, software capabilities, and materials science, which are enhancing efficiency and precision in production.

The integration of artificial intelligence and machine learning into CNC systems is a key trend to watch in the coming years. These technologies enable predictive maintenance, which can reduce downtime and maintenance costs by up to 30%, according to a study by Deloitte. Furthermore, the rise of Industry 4.0 has led to increased connectivity between machines, allowing for real-time data analysis and improving decision-making processes. As manufacturers increasingly adopt these smart technologies, the potential for increased operational efficiency and reduced waste will become more pronounced, making metal CNC an even more attractive option for production needs.